Outer structure of the implants

- Compression make

- Double conical shape

- Double micro groove

- Variable width thread tip

- Spiral holes

- Apical cutting edges

- Microgrooves on the neck area

- Outstanding osseointegration

Insertion: The implant’s threading enables orientation during insertion

Implant body design: Due to its double tapered shape the implant compresses the bone structure and ensures outstanding stability

Double mirogrooving: Microgrooves on the tips and trenches of the thread offer extra stability

Polished, coloured face: Enables bacterial locking, while the colour coding speeds up the surgery

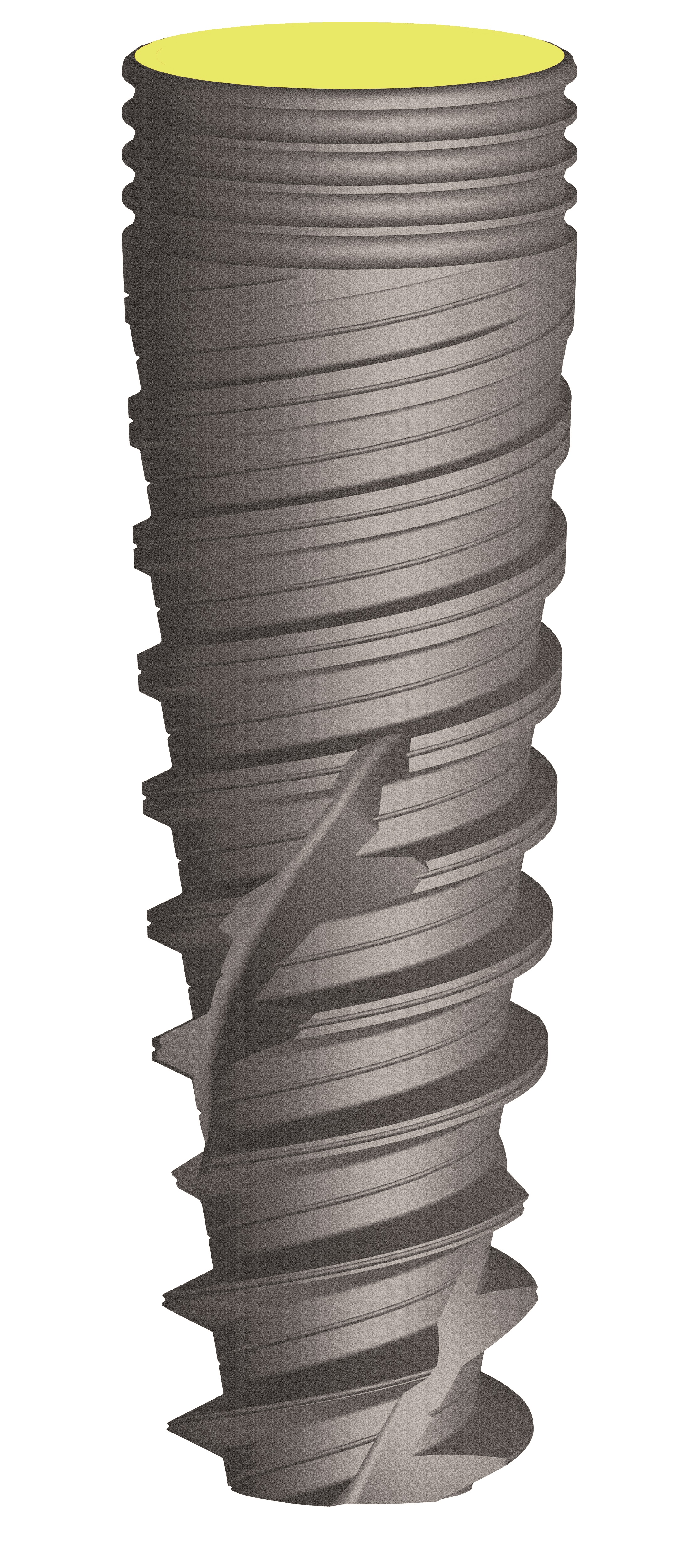

Nexus

Coronal deisgn: Facilitates stability and healing. The micro-grooves provide bacterial locking, whereas the back-tapered top area ensure the maximum level of alveolar bone around the implant

Coronal deisgn: Facilitates stability and healing. The micro-grooves provide bacterial locking, whereas the back-tapered top area ensure the maximum level of alveolar bone around the implant

Double lead thread: Higher pitch, more bone compression

Two-way edges: They compress the bone during inward driving and widen the hole if counterdriven

Apical cutting edges: They help implant orientation during insertion

Varying thread tips: Width of threads increase towards the top of the implant, thus boosting the compression during insertion

BoneTact nano surface: Extremely clean, sandblasted, porotic TiO2 surface, which facilitates osseointegration

| Diameter (mm) | 8 | 10 | 12 | 14 | 16 |

| 3,3 | x | x | x | x | |

| 3,75 | x | x | x | x | x |

| 4,2 | x | x | x | x | x |

| 4,7 | x | x | x | x | x |

| 5,5 | x | x | x | x | x |

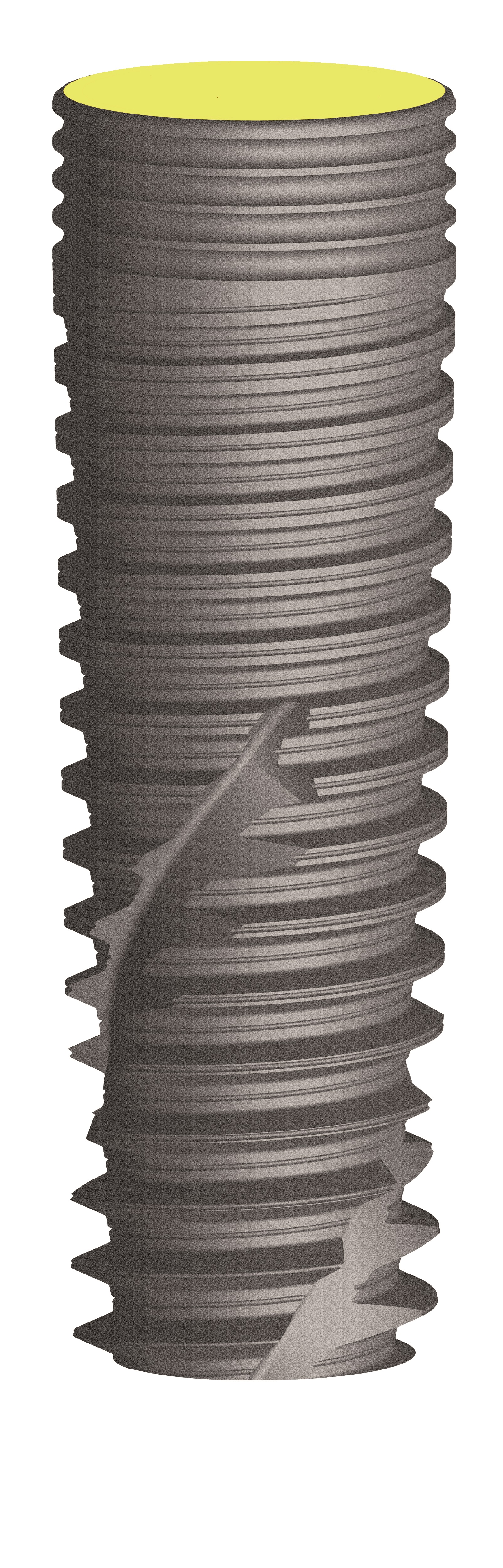

Nexus-D

Coronal deisgn: Facilitates stability and healing. The micro-grooves provide bacterial locking, whereas the back-tapered top area ensure the maximum level of alveolar bone around the implant

Single lead thread: Due to the low pitch, it is ideal for insertion into cortical osteotomy

Two-way edges: They compress the bone during inward driving and widen the hole if counterdriven

Apical cutting edges: They help implant orientation during insertion

Varying thread tips: Width of threads increase towards the top of the implant, thus boosting the compression during insertion

BoneTact nano surface: Extremely clean, sandblasted, porotic TiO2 surface, which facilitates osseointegration

| Diameter (mm) | 8 | 10 | 12 | 14 | 16 |

| 3,3 | x | x | x | x | x |

| 3,75 | x | x | x | x | x |

| 4,2 | x | x | x | x | x |

| 4,7 | x | x | x | x | x |

| 5,5 | x | x | x | x | x |

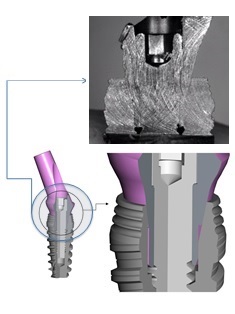

Internal structure

The implant and the abutment are connected by an optimized internal cone. Orientation is ensured by a hexagon under the cone. The connecting screw has a peg ending to block loosening.

-Variable abutments regardless of the implant’s diameter

-Fixation with internal connecting screw

-Precise setting of torque strength (30 Ncm)

-Uniform connecting screw for all sizes

-Decreased rate of micro-movements

-Significant decrase in the possibility of implant loosening